ELISA Auto-wash AW-96-2

Completely automatic washing and drying machine for Microplates

Order No.: 4.0045

The AutoWash AW-96-2 is a completely automatic washing and drying plant for ’96 micro-titration plates. From a pile of test plates in the entrance feeder tower, the plates are laid individually on a transport runner by a plate lifter and carried to the next station by a conveyor under it. At this station, every individual optical cell of the test plate will be washed twice for variable seconds (0-4s adjustable) in each case from above for safety reasons. Subsequently, the test plates will reach a centrifuge, in which they will be dried. Finally, the plates are piled in an exit tower for removal.

The AutoWash AW-96-2 monitors the most important functions completely automatically and, if there are changes to the normal conditions, it will show appropriate messages on a touch panel screen. At the same time, the apparatus distinguishes between status and error messages. These messages are supported optically by a signal light on the entrance feeder tower. Four different blinking or continuous light signals are used, so that it is possible to recognize from a distance what type of message it is. The AutoWash AW-96-2 monitors the most important functions completely automatically and, if there are changes to the normal conditions, it will show appropriate messages on a touch panel screen. At the same time, the apparatus distinguishes between status and error messages. These messages are supported optically by a signal light on the entrance feeder tower. Four different blinking or continuous light signals are used, so that it is possible to recognize from a distance what type of message it is.

For safety reasons, the complete apparatus is operated with 24 VDC.

The structure of this apparatus enables it to be easily dismantled into its individual components, to enable cleaning and maintenance tasks to be carried out as effectively as possible. A high-walled apportioned water trough ensures the optimal protection against sprayed water under the whole path of the plates.

Unlike to the first version this second version of the AW-96 makes no noise during the lifting process, the centrifuge step-motor works without a mechanical brake and the plate conveyor is a stainless steel chain.

|

The washer is placed in a wash-basin and has to be connected to the bib-cock using a

The washer is placed in a wash-basin and has to be connected to the bib-cock using a As additional equipment, we recommend using the MEKU Dosing Unit for adding the washing buffer. The device automatically proportions washing buffer out of a store tank and tap water. The controlling puls is generated by a special water meter and therefore is independant of the sort and count of washing machines used in the laboritory.

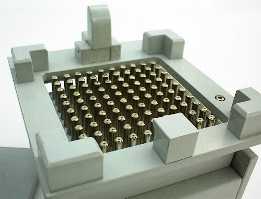

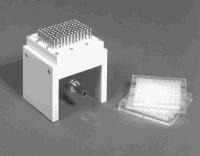

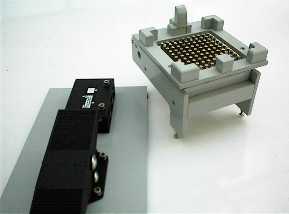

As additional equipment, we recommend using the MEKU Dosing Unit for adding the washing buffer. The device automatically proportions washing buffer out of a store tank and tap water. The controlling puls is generated by a special water meter and therefore is independant of the sort and count of washing machines used in the laboritory. Like all MEKU ELISA devices, the washing machine for microplates is solving a fundamental problem in daily laboratory work. After incubation of the test plate, a smooth and even washing process may be carried out by means of the special washing nozzles, which operate on the whole plate at once. During the washing process, two plates are positionend on the washing heads upside down, held by means of a guide on three of the nozzles, ensuring a stable position. The working principles eleminates suction of liquid, so no clogging of the nozzles may occur.

Like all MEKU ELISA devices, the washing machine for microplates is solving a fundamental problem in daily laboratory work. After incubation of the test plate, a smooth and even washing process may be carried out by means of the special washing nozzles, which operate on the whole plate at once. During the washing process, two plates are positionend on the washing heads upside down, held by means of a guide on three of the nozzles, ensuring a stable position. The working principles eleminates suction of liquid, so no clogging of the nozzles may occur.

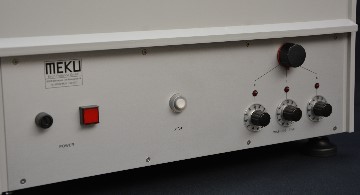

The washer may be started with a key button on the front panel. Washing time is controlled automatically as preset before the washing process. The six head machine is able to process two, four or six plates, rinsing the plates in pairs one after the other. Thus, fast and continuous work is possible with drying the plates on the MEKU Blow-Out-Dryer (see options).

The washer may be started with a key button on the front panel. Washing time is controlled automatically as preset before the washing process. The six head machine is able to process two, four or six plates, rinsing the plates in pairs one after the other. Thus, fast and continuous work is possible with drying the plates on the MEKU Blow-Out-Dryer (see options). The AutoWash AW-96-2 monitors the most important functions completely automatically and, if there are changes to the normal conditions, it will show appropriate messages on a touch panel screen. At the same time, the apparatus distinguishes between status and error messages. These messages are supported optically by a signal light on the entrance feeder tower. Four different blinking or continuous light signals are used, so that it is possible to recognize from a distance what type of message it is.

The AutoWash AW-96-2 monitors the most important functions completely automatically and, if there are changes to the normal conditions, it will show appropriate messages on a touch panel screen. At the same time, the apparatus distinguishes between status and error messages. These messages are supported optically by a signal light on the entrance feeder tower. Four different blinking or continuous light signals are used, so that it is possible to recognize from a distance what type of message it is.  Praxis has shown how difficult and time consuming drying of microplates may be after the washing cycle. Even by knocking out the plate on a cloth, small water drops may rest on the cavity bottom. Drying is essential for getting a correct dilution.

Praxis has shown how difficult and time consuming drying of microplates may be after the washing cycle. Even by knocking out the plate on a cloth, small water drops may rest on the cavity bottom. Drying is essential for getting a correct dilution.